Contact Information

Mobile phone/WeChat: +8618653133198

E-mail:dragontechcnc@hotmail.com

Address: 2332C, Building 1, Aosheng Building, 1166 Xinling Street, Jinan District, China (Shandong) Pilot Free Trade Zone

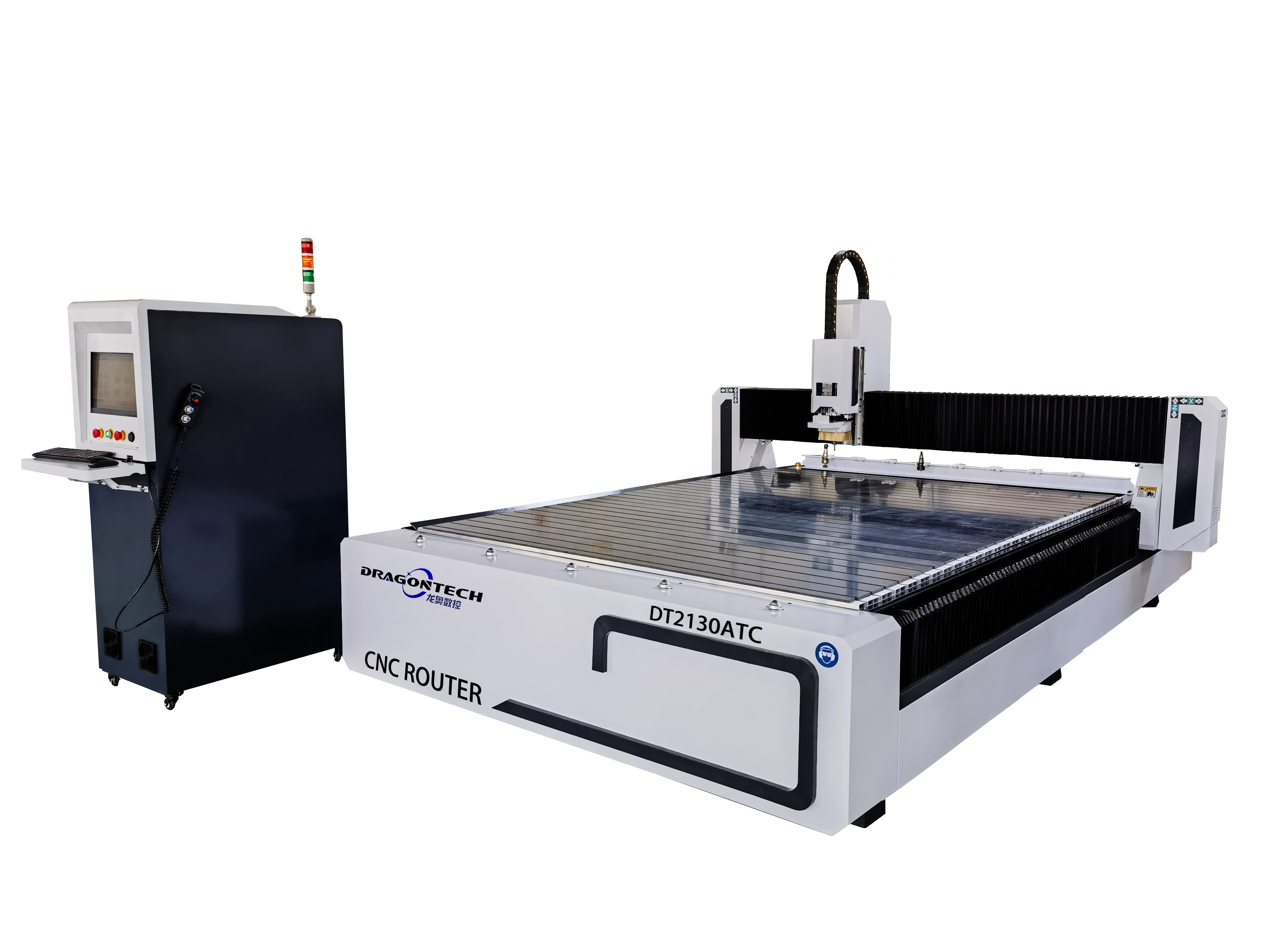

Four-axis CNC ROUTER

Italy imported spindle, spindle -90 degrees swing, Taiwan's new generation CNC system, Japan Yaskawa servo drive.

Four axis machining center: a new choice for process upgrading and non planar machining

In the field of modern industrial processing, mechanical equipment is constantly upgraded to meet more complex and diverse processing needs. As one of them, the four axis machining center, based on the mature technology of the three-axis engraving machine, further enhances its processing capability. So, what is a four axis machining center? In which fields does it have application value? Next, we will delve deeper into this issue.

The four axis machining center was developed based on the three-axis engraving machine, and its core feature is the addition of a B-axis for the main spindle to swing left and right. The addition of this technology enables machines to perform more precise carving, cutting, and other operations on curved surfaces. This innovative breakthrough has brought broader application space to the processing field.

Firstly, four axis machining centers are widely used in the furniture manufacturing industry. Taking the chair seat and chair back as examples, these non planar curved structures are difficult to achieve fine machining on traditional three-axis engraving machines. The introduction of a four axis machining center solves this problem, enabling efficient and accurate carving and cutting on complex surfaces.

In addition, for the woodworking industry, four axis machining centers also have extremely high application value. On the surface carving of coffins, it is difficult for traditional techniques to achieve difficult curved shapes or finely patterned depictions. The four axis machining center, with its outstanding ability to operate on curved surfaces, has brought revolutionary changes to the woodworking industry. Not only has it improved work efficiency, but it has also brought the accuracy and complexity of carving to new heights.

Specifically, the B-axis swing function of the four axis machining center allows the tool to better adapt to changes in the surface of the workpiece during machining, thereby achieving precise operations on the curved surface. This feature enables machines to cope with a wider range of processing fields, not limited to planar or simple three-dimensional structures, but truly moving towards more complex non planar processing.

In short, the four axis machining center is an important technological innovation in modern industrial processing. The application of its B-axis swing function greatly expands the scope of the machining field, improves the accuracy and efficiency of machining. In the fields of furniture manufacturing, woodworking and carving, four axis machining centers have shown great potential for application. With the continuous advancement of technology, four-axis machining centers will play an important role in more fields in the future.

|

Serial Number |

Description |

Model: DT4A**** |

|

1 |

X, Y, Z, B working size |

1300*2500*400~700mm, ±90° |

|

2 |

Gantry |

Steel tube |

|

3 |

Lathe structure |

Welding Steel tube Frame |

|

4 |

X Y structure |

Helical Rack pinion, HIWIN linear Rails |

|

5 |

Z structure |

Ball screw, HIWIN linear Rails |

|

6 |

Repositioning accuracy |

± 0.03/300mm |

|

7 |

System resolution |

± 0.001mm |

|

8 |

Max. travelling speed |

20m/min |

|

9 |

Max. working speed |

15m/min |

|

10 |

Control system |

Ncstudio NK300 (Option: Syntec...) |

|

11 |

Spindle |

9kw ATC spindle |

|

12 |

Tool changing mode |

Carousel magazine, 10 pcs |

|

13 |

Spindle speed |

24000RPM |

|

14 |

Working mode |

Panasonic servo motors (Option: Yaskawa...) |

|

15 |

Working voltage |

AC 380V/3Ph or 220V/3Ph |

|

16 |

Lubricating system |

Automatic lubricating pump |

Key words:

Message consultation