Contact Information

Mobile phone/WeChat: +8618653133198

E-mail:dragontechcnc@hotmail.com

Address: 2332C, Building 1, Aosheng Building, 1166 Xinling Street, Jinan District, China (Shandong) Pilot Free Trade Zone

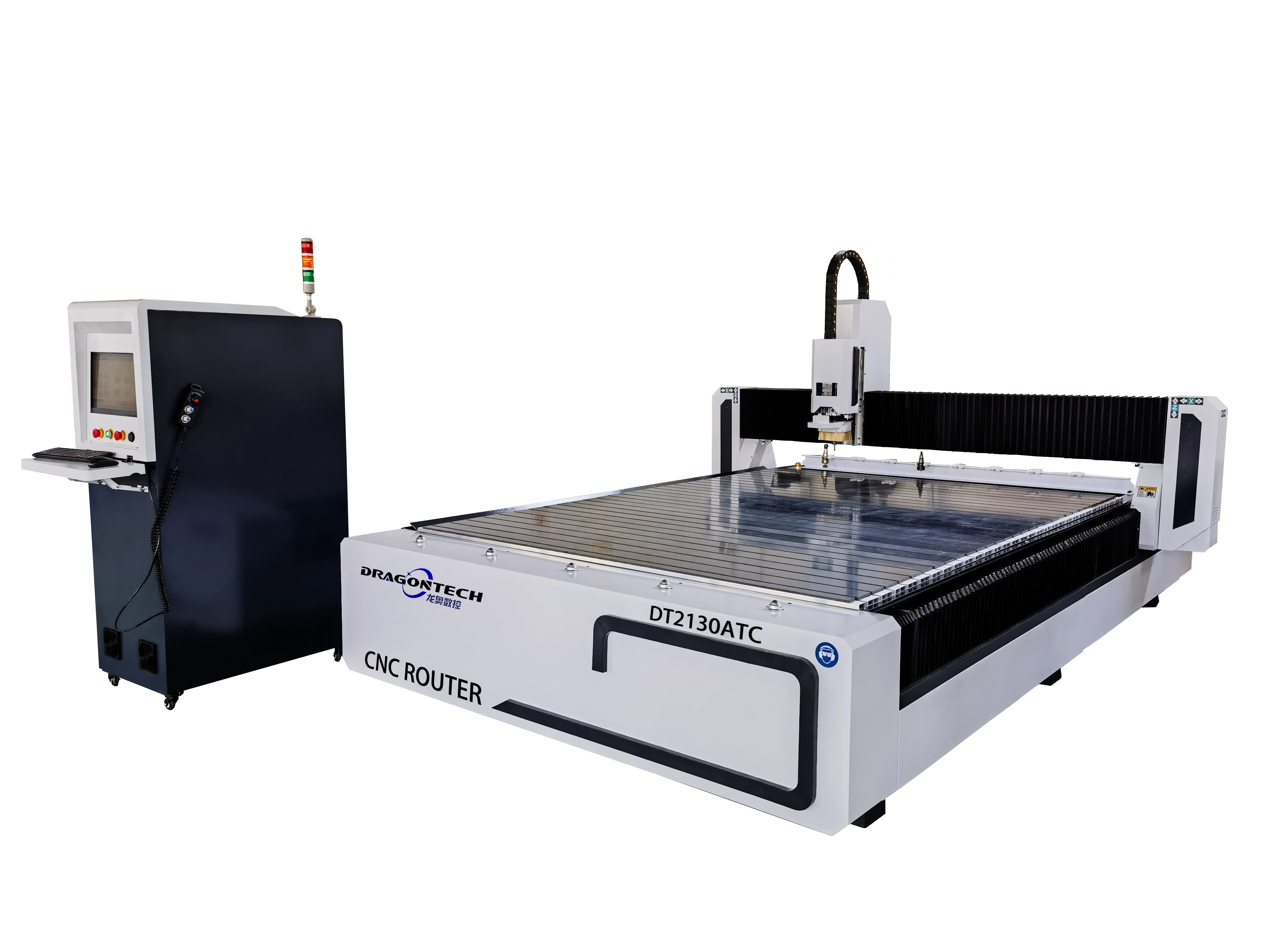

ATC series CNC ROUTER

ATC CNC ROUTER

The application and advantages of automatic tool changing system in CNC Router

As a high-precision mechanical processing equipment, CNC Router are widely used in various fields, especially in the processing of complex workpieces. As an important component of CNC Router, the automatic tool changing system's functions and advantages are increasingly prominent in modern industrial processing.

1、 Overview of Automatic Tool Change System

The automatic tool change system refers to a system in which the CNC Router can automatically change tools during the machining process without the need for manual intervention. This system can greatly improve the work efficiency and processing accuracy of CNC Router, reduce the difficulty and cost of operation.

2、 Improve work efficiency

In the process of CNC Router processing, tool replacement is an important step and a key factor affecting work efficiency. The traditional tool changing process requires manual operation and is time-consuming. The automatic tool change system can automatically complete the replacement of tools during machine operation, greatly saving tool change time and improving work efficiency.

3、 Improve workpiece accuracy

The automatic tool change system not only allows for quick tool replacement, but also ensures the accuracy of the tool change process. In the processing of complex workpieces, multiple different specifications and types of cutting tools are required, and manual tool replacement is difficult to avoid errors. The automatic tool change system ensures precise tool alignment after each tool change through a precise control system, thereby improving the machining accuracy of the workpiece.

4、 Reduce operational difficulty and cost

The application of automatic tool changing system reduces the difficulty of operation. Operators only need simple settings to achieve automatic tool changing without the need for professional skills. In addition, the automatic tool change system can also reduce tool wear and waste, reduce tool inventory and management costs, and thus lower overall processing costs.

5、 Suitable for processing complex workpieces

The automatic tool changing system has shown great advantages in complex workpiece processing. Complex workpieces require multiple types of cutting tools for combined processing, requiring high precision and speed in tool replacement. The automatic tool changing system can quickly and accurately replace tools, meeting the processing needs of complex workpieces.

In summary, the application of automatic tool changing system in CNC Router can greatly improve the work efficiency and workpiece accuracy of engraving machines, reduce operational difficulties and costs, and is particularly suitable for processing complex workpieces. With the continuous development of technology, automatic tool changing systems will play a more important role in the field of engraving machines in the future.

|

No. |

Description |

Model: DT****ATC |

|

1 |

Max. X, Y, Z working size |

2100*6000*400mm |

|

2 |

Gantry |

8mm Steel tube |

|

3 |

Lathe structure |

Welding Steel tube Frame |

|

4 |

X Y structure |

Helical Rack pinion, HIWIN linear Rails |

|

5 |

Z structure |

Ball screw, HIWIN linear Rails |

|

6 |

Repositioning accuracy |

± 0.03/300mm |

|

7 |

System resolution |

± 0.001mm |

|

8 |

Max. travelling speed |

60m/min |

|

9 |

Max. working speed |

25m/min |

|

10 |

Operating system |

Syntec 6MB (Ncstudio, Mach 3 ...) |

|

11 |

Spindle |

9KW ATC spindle |

|

12 |

Tool changing mode |

Carousel magazine 10 pcs (Linear magazine) |

|

13 |

Spindle speed |

24000RPM |

|

14 |

Working mode |

Panasonic servo (Yaskawa...) |

|

15 |

Working voltage |

AC 380V/3Ph 220V/3Ph |

|

16 |

Lubricating system |

Automatic lubricating pump |

Message consultation