Contact Information

Mobile phone/WeChat: +8618653133198

E-mail:dragontechcnc@hotmail.com

Address: 2332C, Building 1, Aosheng Building, 1166 Xinling Street, Jinan District, China (Shandong) Pilot Free Trade Zone

Huge Four or Five axes machining Center

Introduction to Large Four/Five Axis Machining Centers

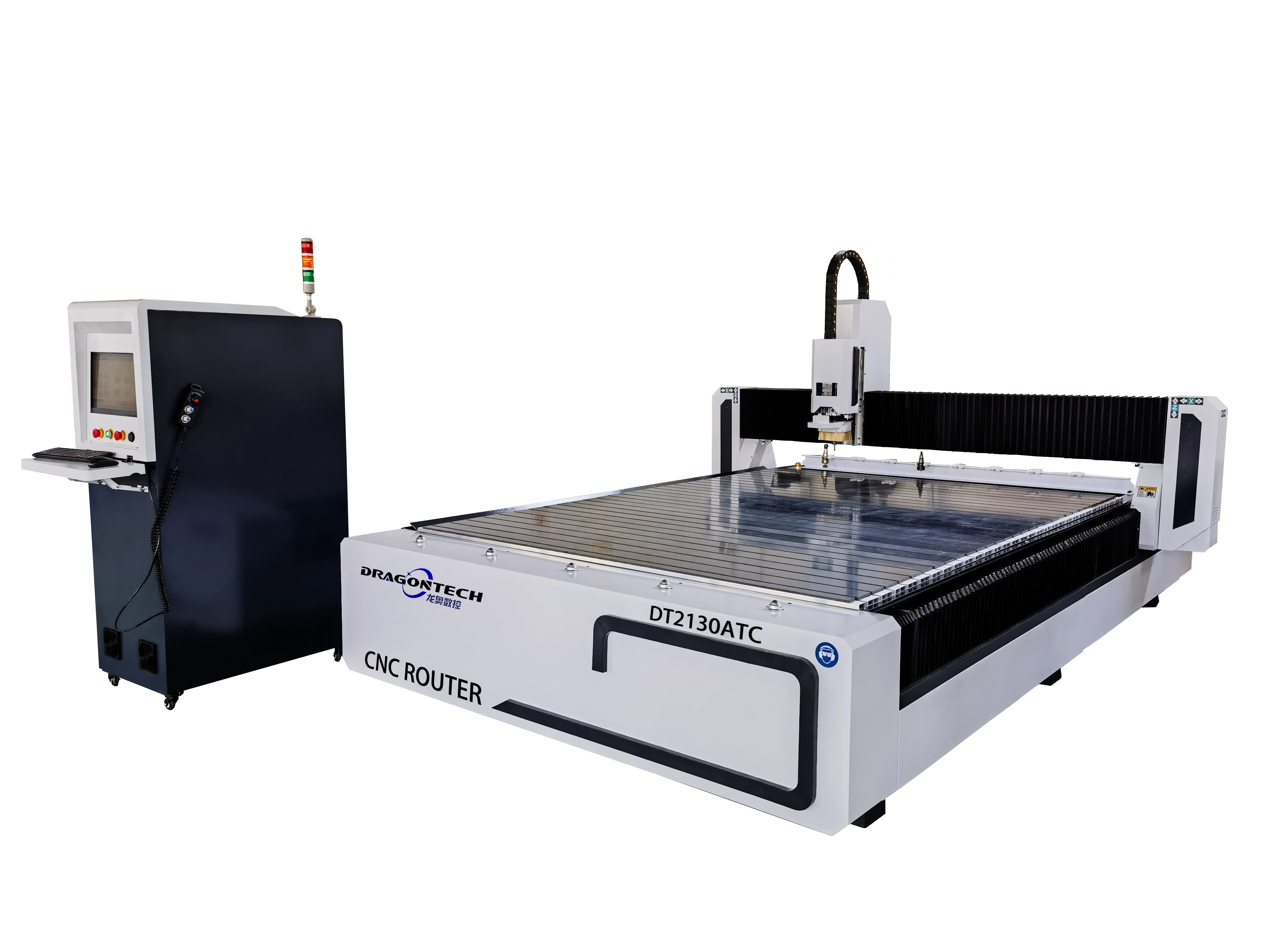

Our large four/five axis machining center is an efficient and precise equipment widely used in various industrial and artistic processing fields. This machine is composed of left and right pillars, bed body, gantry, machine head, and other parts, with a unique design and excellent performance.

1、 Machine construction

The columns, bed body, and gantry of this machining center are welded with high-strength 8mm square tubes. To ensure the stability and durability of the machine, all components have undergone strict annealing treatment to eliminate stress during the welding process. In addition, we have also finely processed each connecting surface to ensure the precision of the machine assembly after completion.

2、 High precision machining

Our machining center is equipped with high-precision machine heads, which can achieve the processing of various complex workpieces. In addition, our ultra-high Z-axis design allows the machine to process large workpieces, meeting the diverse needs of customers.

3、 Widely applied

1. Casting industry: This machine is suitable for processing large lost foam molds, aluminum molds, wood molds and other commonly used molds in the casting industry, and can meet the precision processing needs of various molds.

2. Stage props: Due to the high precision and large processing capacity of this machine, it can also be used to process various stage props, creating more value for customers.

3. Other fields: In addition, the machine can also be applied in aviation, automotive, mold, mechanical processing and other fields to achieve precision machining of various workpieces.

4、 High quality service

We are committed to providing customers with high-quality service. We will provide professional technical support and solutions for the selection, installation, debugging, and after-sales maintenance of machines. Our goal is to ensure that customers can fully utilize our equipment and achieve maximum production efficiency.

In summary, our large four axis/five axis machining center is a high-performance and high-precision equipment suitable for various industrial processing fields. Our machines have a stable structure, high-precision processing capabilities, and wide applicability, which can meet the diverse needs of customers. We look forward to working with you to create a better future together.

|

Size |

Max. Working area |

2500*6000*1000mm (A ±100°, C ±225°) or 600*900*700mm*2 (A ±100°, C ±225°) |

|

Accuracy |

Positioning accuracy |

0.01mm |

|

Repeatalibity accuracy |

±0.015mm |

|

|

Control system |

|

Osai or Siemens or Syntec |

|

Spindle |

Spindle type |

HSD 5 axis spindle |

|

Spindle speed |

24000RPM |

|

|

Tool Change |

Automatic |

Tool holder change, 12~24 PCS Carousel Magazine |

|

Table structure |

Material hold down |

T-slot table+Suction cups |

|

Transmission system |

Driving system |

Yaskawa/Panasonic/Siemens servo system |

|

Transmission system |

TBI Ball screw, Helical Rack and Hiwin square rail |

|

|

Max. travelling speed |

X, Y = 35 m/min |

|

|

Lubrication |

Automatic |

Automatic lubrication system |

|

Power source |

|

220V or 380V, 3 phase (50/60 Hz) |

Key words:

Message consultation