Contact Information

Mobile phone/WeChat: +8618653133198

E-mail:dragontechcnc@hotmail.com

Address: 2332C, Building 1, Aosheng Building, 1166 Xinling Street, Jinan District, China (Shandong) Pilot Free Trade Zone

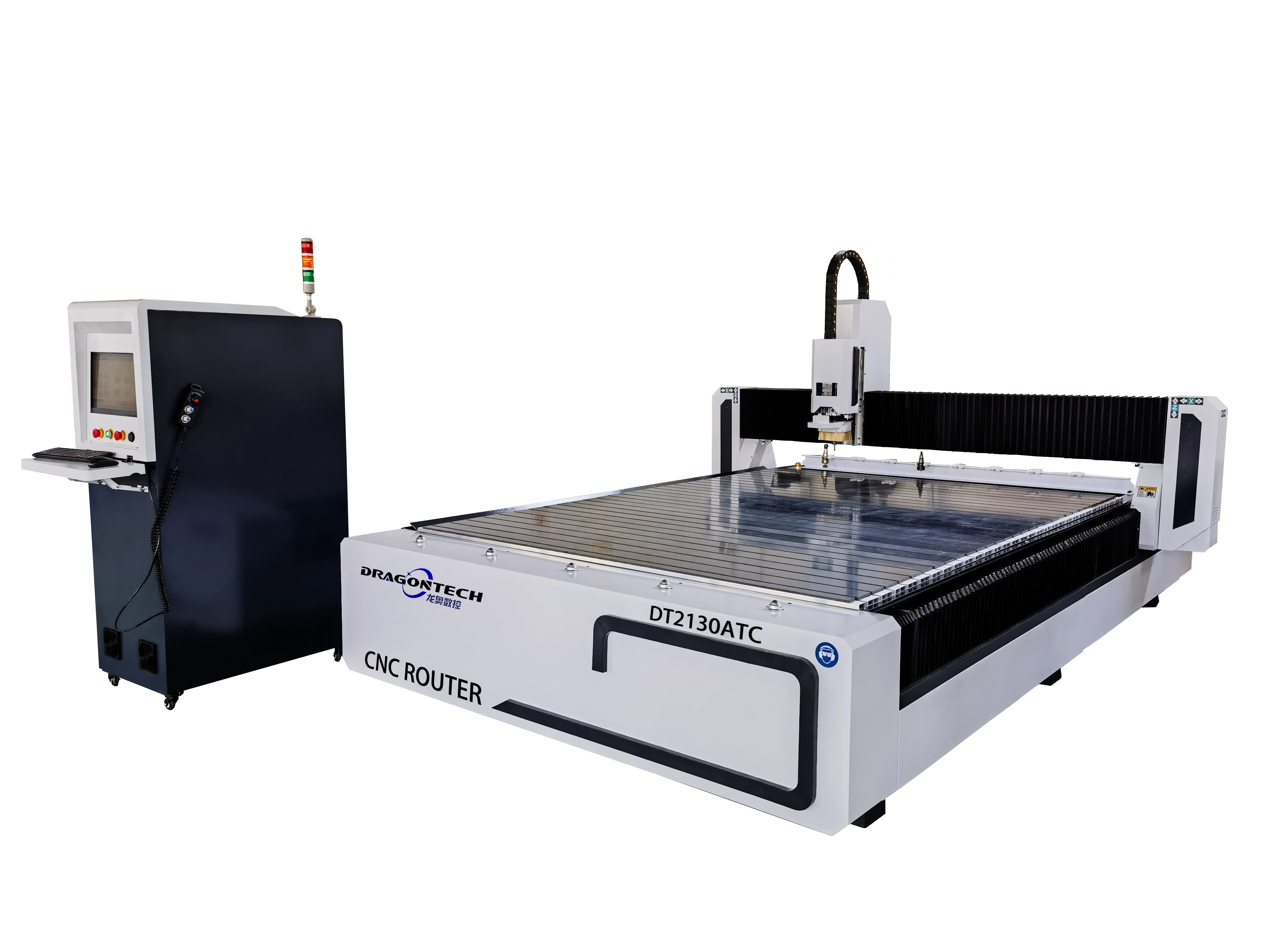

CNC ROUTER for stone DTS series

Suitable for three-dimensional relief of natural marble, granite, bluestone, sandstone, artificial stone, tombstone, milestone, etc., as well as line carving, cutting, chambered, drilling, and two-dimensional carving.

Our stone CNC router is designed with a heavy reinforced bed body, which ensures stability and durability during the machining process. This allows for precise and accurate cutting, engraving, and shaping of stone materials with ease.

Additionally, the stainless steel sink countertop provides a convenient space for storage and circulation of coolant. This helps to keep the machine and work area clean and free of debris, while also ensuring that the stone material remains cool and lubricated during the machining process.

The advantages of our stone CNC router include:

1. Precise and accurate machining of stone materials

2. Heavy reinforced bed body for stability and durability

3. Stainless steel sink countertop for storage and circulation of coolant

4. Clean and organized work area

5. Easy maintenance and upkeep of the machine

Overall, our stone CNC router is a reliable and efficient tool for stone fabrication and processing, making it an ideal choice for businesses in the stone industry.

|

Dimensions |

Scope of Work |

1300*2500 * 300mm (rotating shaft diameter: 200mm) |

|

Accuracy |

Positioning accuracy |

0.01mm |

|

Repeated positioning accuracy |

±0.03mm |

|

|

Control System |

|

RichAuto A11E, Weihong, Mach 3 |

|

Spindle |

Spindle |

4.5~6kw water cooled spindle |

|

Spindle speed |

24000 RPM |

|

|

Table structure |

Workpiece fixing method |

T-slot |

|

Drive system |

Driving system |

Stepper/servo Motors & Drivers |

|

Transmission system |

TBI ball screw, Hiwin/PMI linear rails |

|

|

Maximum travelling speed |

X, Y = 25 m/min |

|

|

Tool cooling |

|

Water spray cooling |

|

Power |

|

Three-phase 380V or three-phase 220V(50/60Hz) |

Key words:

Message consultation