Contact Information

Mobile phone/WeChat: +8618653133198

E-mail:dragontechcnc@hotmail.com

Address: 2332C, Building 1, Aosheng Building, 1166 Xinling Street, Jinan District, China (Shandong) Pilot Free Trade Zone

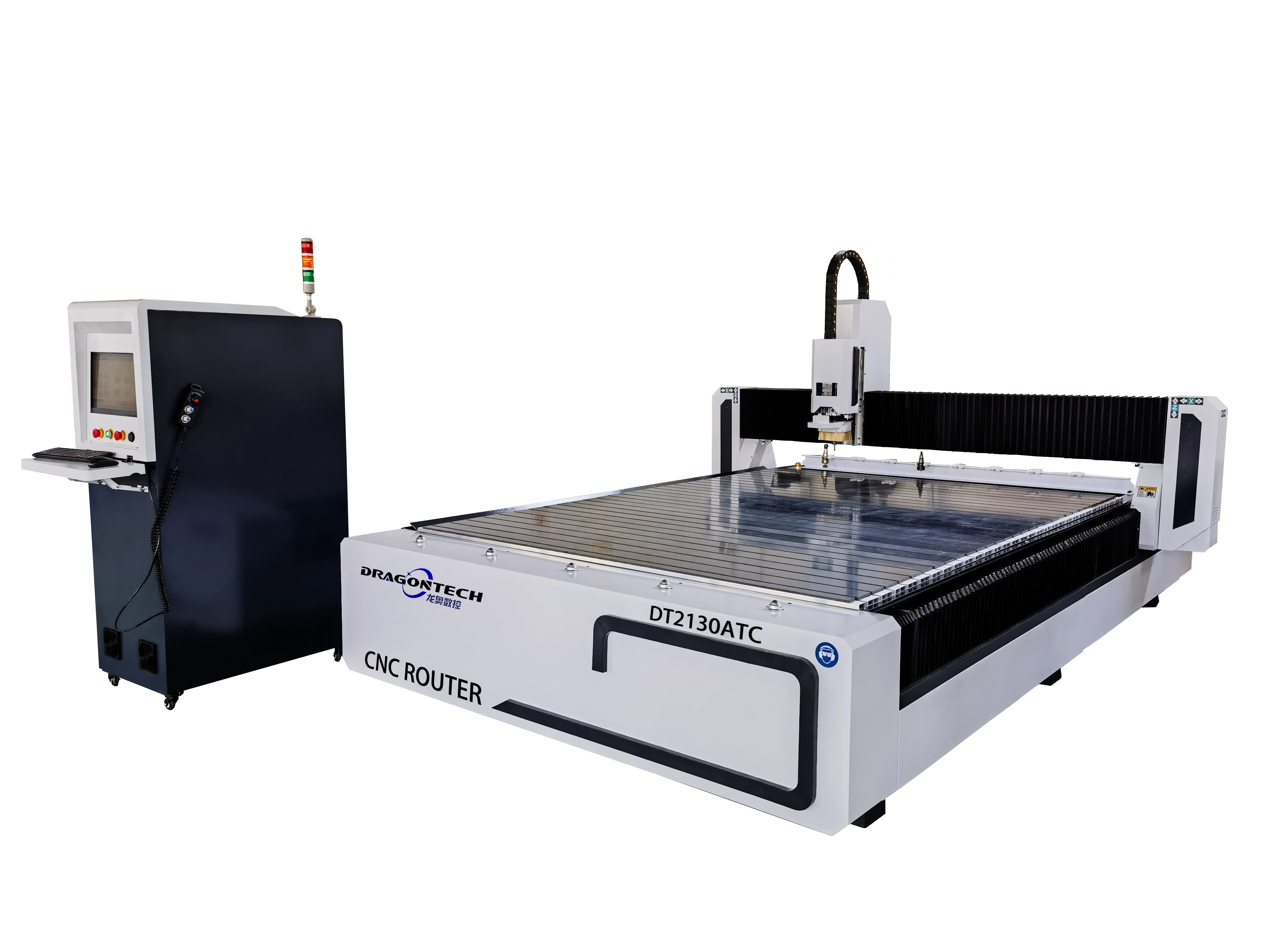

Multi-process woodworking CNC ROUTER

Compared with the single-headed woodworking engraving machine, the three processes can carry out complex engraving groups, and process various more complex and exquisite tones, reliefs, etc.

Multi process woodworking CNC routers are equipped with multiple spindles that can automatically rotate during the cutting process. This innovative feature allows the machine to perform multiple operations simultaneously, increasing productivity and efficiency in woodworking projects.

One of the key advantages of a multi process CNC router is the implementation of an automatic tool changer (ATC) function at a lower cost. The ATC function allows the machine to change cutting tools automatically, reducing downtime and increasing the overall efficiency of the woodworking process. This feature is particularly useful for projects that require different types of cutting tools or multiple tool changes during operation.

Additionally, the multi spindle automatic rotation working mode of a multi process CNC router helps to improve work efficiency. By utilizing multiple spindles to perform different operations at the same time, the machine can complete tasks more quickly and accurately than traditional single spindle routers. This results in faster production times and higher output levels, making it an ideal choice for woodworking businesses looking to increase their productivity.

Overall, the core advantage of a multi process woodworking CNC router lies in its ability to enhance efficiency, reduce costs, and improve productivity in woodworking projects. With its innovative features and advanced technology, this type of machine offers a competitive edge for businesses looking to stay ahead in the woodworking industry.

|

Dimensions |

X Y Z |

1300~2500mm 2500~6000mm 200~400mm |

|

Accuracy |

Positioning accuracy |

0.01mm |

|

Repeated positioning accuracy |

±0.02mm |

|

|

Control System |

|

WeiHong,Mach3... |

|

Spindle |

Spindle |

3 or 4 spindles, 3~6kw |

|

Spindle speed |

18000 RPM |

|

|

Tool change mode |

Automatic |

Spindles rotation |

|

mesa structure |

Workpiece fixing method |

T-groove vacuum adsorption |

|

Drive system |

Driving system |

Leadshine Hybrid Servo |

|

Transmission system |

TBI ball screw, Hiwin/PMI linear rails |

|

|

Max. travelling speed |

X, Y = 50 m/min |

|

|

Lubrication method |

Automatical/Manual |

Automatical/Manual lubricating pump |

|

Power |

|

Three-phase 380V or three-phase 220V(50/60Hz) |

Message consultation