Contact Information

Mobile phone/WeChat: +8618653133198

E-mail:dragontechcnc@hotmail.com

Address: 2332C, Building 1, Aosheng Building, 1166 Xinling Street, Jinan District, China (Shandong) Pilot Free Trade Zone

DTC1325 of discharge drilling machine

Disc-type tool changing magazine, imported drilling system; Panel furniture automatic order removal software, double-layer adsorption table top, automatic loading and unloading function, cutting, drilling and milling grooves in one go, fast speed, high efficiency, time-saving, material-saving and labor-saving.

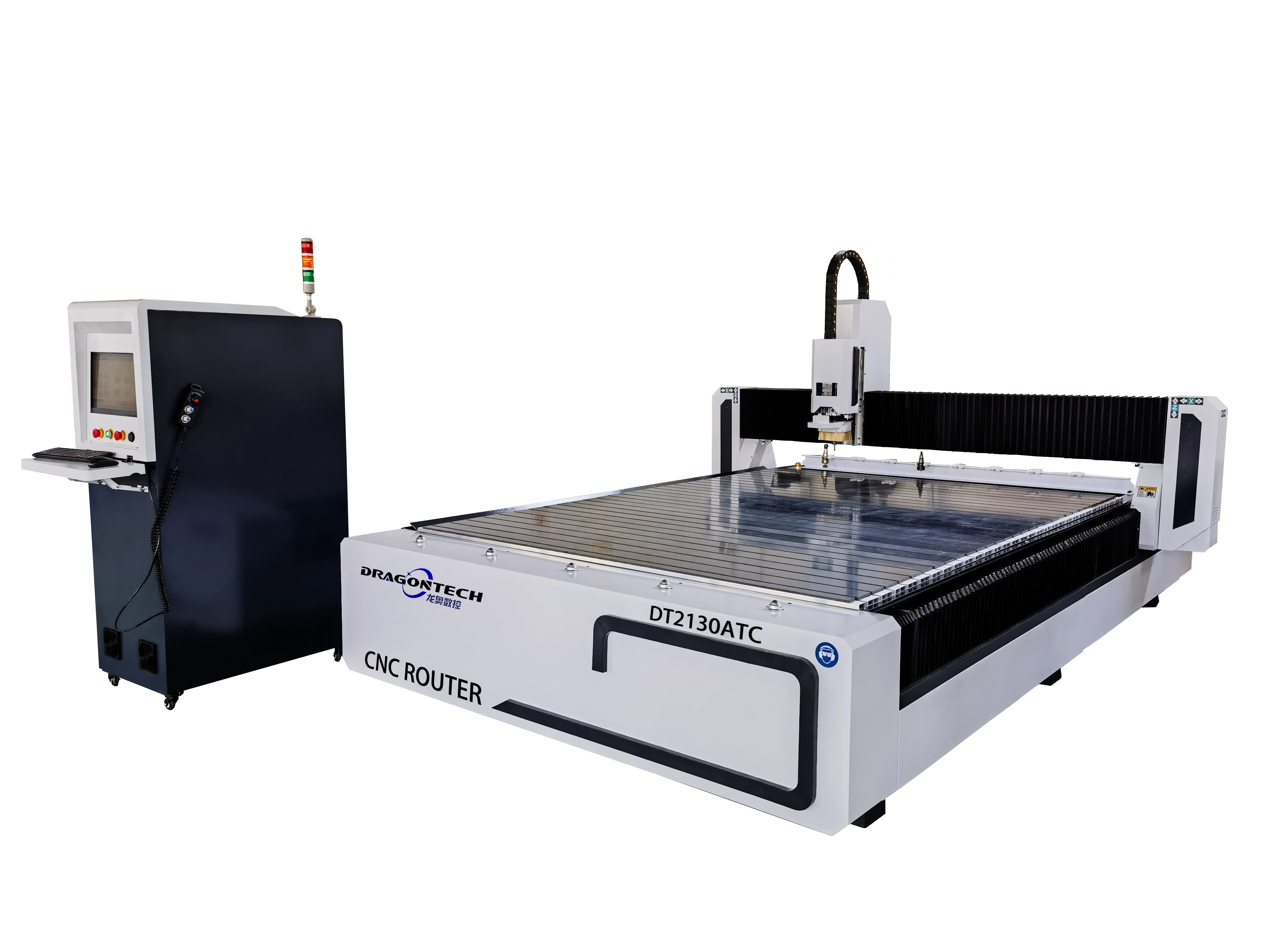

CNC routers are a popular tool for cutting and shaping materials such as wood, plastic, and metal. One of the main advantages of CNC routers is their ability to automate the cutting process, which can save time and labor costs.

Automatic feeding CNC routers take this automation to the next level by not only cutting materials, but also loading and unloading them automatically. This means that operators can set up a job, press start, and walk away while the machine completes the entire process from start to finish.

This greatly improves work efficiency, as operators can focus on other tasks while the machine is running. It also saves labor costs, as fewer operators are needed to run the machine. In addition, automatic feeding CNC routers can often run continuously without breaks, further increasing productivity.

Overall, automatic feeding CNC routers are a valuable tool for businesses looking to streamline their production processes and improve efficiency. By automating loading and unloading operations, these machines can help businesses save time, money, and labor costs while incre

|

Serial Number |

Description |

Model: DTC1325 |

|

1 |

X, Y, Z working size |

1300*2500*200mm |

|

2 |

Gantry |

Steel tube |

|

3 |

Lathe structure |

Welding Steel tube Frame |

|

4 |

Automatic Lift Platform |

Height 300~700mm, 1000kg |

|

5 |

X Y structure |

Helical Rack pinion, HIWIN linear Rails |

|

6 |

Z structure |

Ball screw, HIWIN linear Rails |

|

7 |

Repositioning accuracy |

± 0.03/300mm |

|

8 |

System resolution |

± 0.001mm |

|

9 |

Max. travelling speed |

50m/min |

|

10 |

Max. working speed |

25m/min |

|

11 |

Control System |

Ncstudio NK300 (Option: Syntec...) |

|

12 |

Spindle |

1*4.5kw 2*3kw air coolant sindle |

|

13 |

Boring unit |

FAM, 9 vertical 2 sidewards 2 saws |

|

14 |

Tool changing mode |

Spindle rotation |

|

15 |

Spindle speed |

18000RPM |

|

16 |

Working mode |

Panasonic servo motors (Option: Yaskawa...) |

|

17 |

Working voltage |

AC 380V/3Ph |

|

18 |

Lubricating system |

Automatic lubricating pump |

|

19 |

Packing size |

5200*2250*2200mm |

|

20 |

Gross weight |

2500kgs |

Key words:

Message consultation